Table of Contents

Volumetric feeder for dry sediment. From the manufacturer's website:

Instead of incorporating traditional internal stirring or vibration devices to keep material moving, Schenck AccuRate pioneered the preferred Tuf-Flex™ seamless vinyl hopper, that is externally massaged by two agitation paddles. Material is conditioned to a uniform bulk density, evenly filling the flights of the feed screw, eliminating ratholing and bridging. The result is excellent volumetric accuracy. Volumetric feeding deviations range from +/-0.5% to 3% for most materials.

1 General Product Specifications

1.1 Dimensions

- Lenght: 21.74” (552 mm)

- Width: 21.74” (552 mm)

- Depth: 15.77” H (401 mm)

- Weight: 155 lbs.

1.2 Feed rates

0.0008 - 48 cubic feet per hour, depending on the available helix.

1.3 Helix sizes

0.50”, 0.75”, 1.00”, 1.38”, 1.75”, 2.25”

1.4 Vinyl Hopper Capacity

0.9 cubic feet.

1.5 Electrical Requirements

110 VAC (220 VAC optional) 50/60 Hz, single phase.

1.6 Control modules

Dual controls: Separate control of agitation speed and screw speed.

For additional specifications, see the product brochure.

2 Experimental Setups

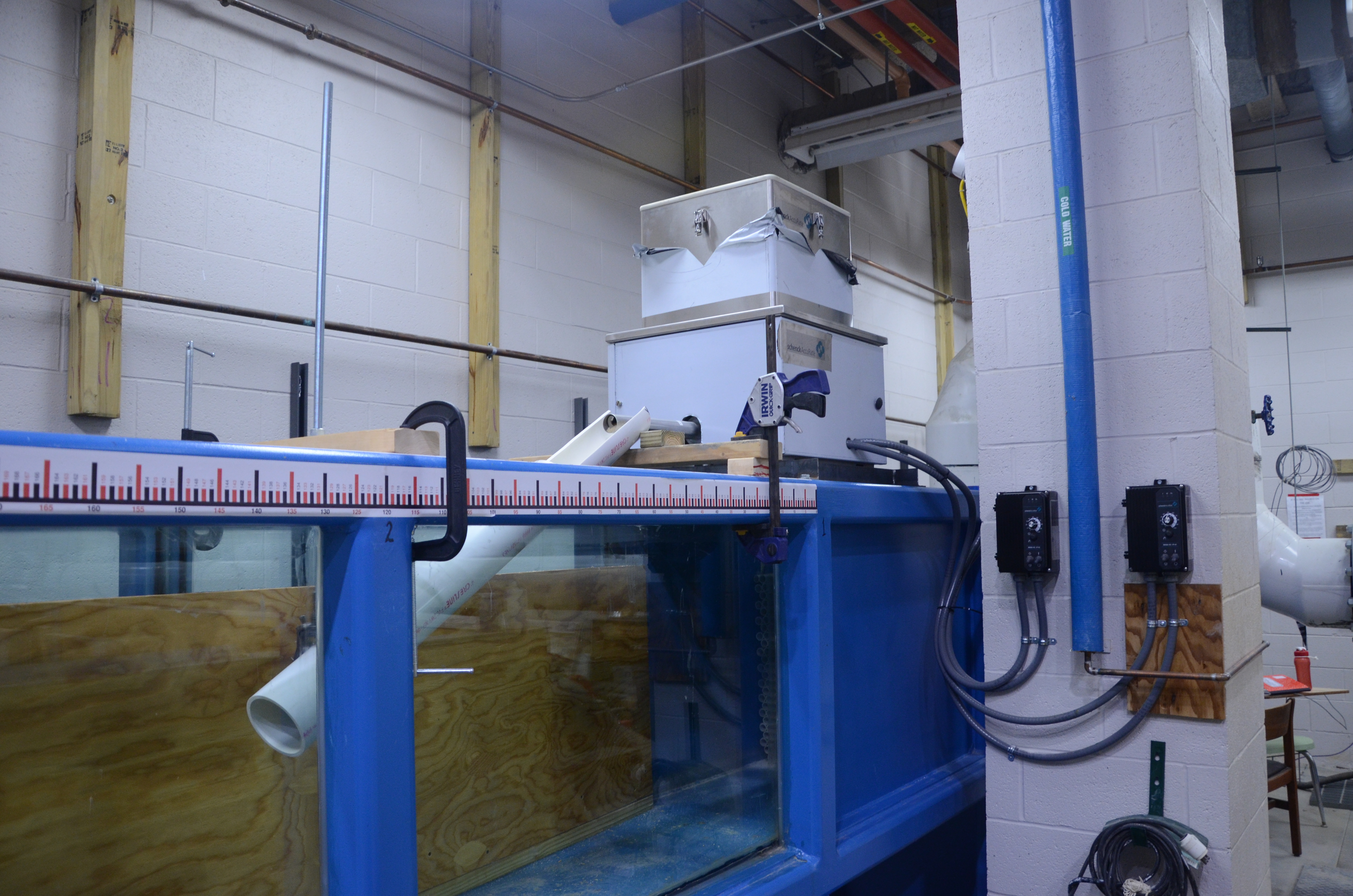

2.1 Unidirectional, sediment-feed, tilting flume of the University of South Carolina at Columbia

The Schenk Accurate 600 installed in this setup is a model 604, dual-drive, with available helix sizes of 1.38", 1.75" and 2.25".

The mass feed rates for well-sorted silica sand of Dg = 1.11 mm range between 75 g/min and 20,000 g/min.